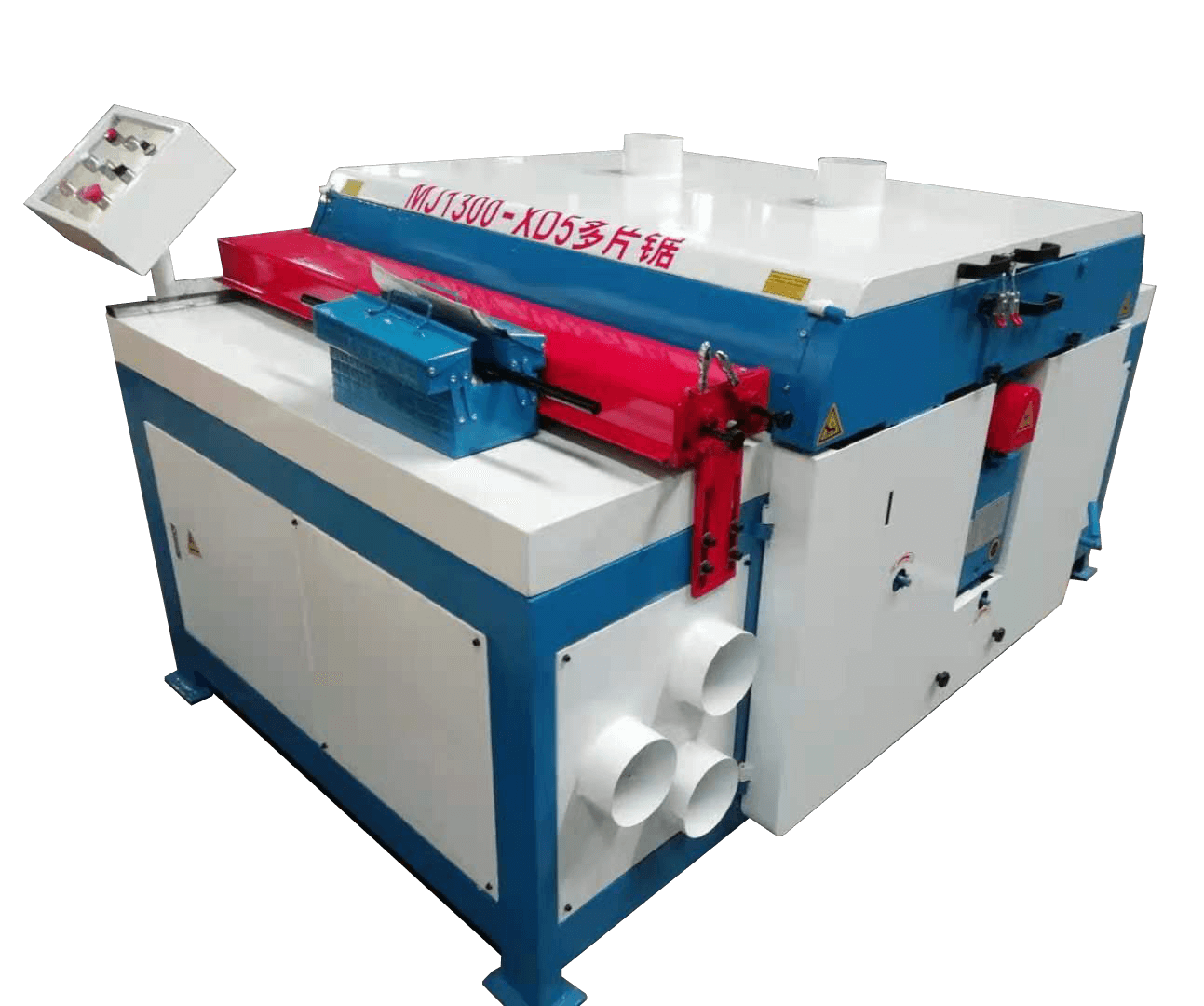

Multiple blade saw MJ1300-XD5

- ¥0.00

- ¥0.00

- Unit price

- per

Couldn't load pickup availability

Packing method

Freight Standards based on the weight and cubic volume

Confirm specifications with customer service to ensure cost-effectiveness.

Warranty: 12 months

Ex Works

12 Months Warranty

x1. The quality guarantee period for the products under this contract is: 12 months from the date of purchase.

2. During the warranty period, we provide free quality warranty services for the equipment within the scope of the warranty.

3. The following items are not included in the warranty scope:

- Wear - and - tear parts;

- Parts and labor costs caused by improper operation or man - made damage by yourself;

- Parts and labor costs caused by unstable voltage;

- Equipment damage caused by improper transportation by the carrier;

- Damage caused by various disasters;

- Equipment damage caused by yourself - replacement of parts;

- Malfunctions or damages caused by your entrusting non - SHANGRUI staff to disassemble and repair the equipment without permission or conduct unauthorized modifications.

Please attention!!!

xRefunds are available for standard off-the-shelf devices before shipment, except that deposits for custom-made devices are non-refundable. Post-delivery refunds are permitted only for unopened standard devices in original packaging.

- Before placing orders:

- Contact customer service for stock status and promo codes

- Cross-border policies vary:

- Contact customer service for customs and after-sale terms.

- Wholesale:

- Contact us for custom quotes and logistics plans prior to order.

- Custom orders:

- Contact us to confirm specifications before ordering.

Related Products

Recently Viewed Products

- Choosing a selection results in a full page refresh.